Rongsheng: Professional Manufacturer of UHP Graphite Electrodes for Electric Arc Furnaces. In today’s steelmaking industry, where efficiency, power, and sustainability define competitiveness, UHP graphite electrodes stand as a key technological component. Designed for the most demanding melting operations, these electrodes deliver superior conductivity, mechanical strength, and heat resistance — making them indispensable in electric arc furnaces (EAFs).

As a global manufacturer and supplier, Rongsheng has established itself as a leader in the production of high-quality electric arc furnace electrodes, built from carefully selected raw materials for electrodes and crafted with advanced manufacturing processes. With clients in over 120 countries, Rongsheng’s products help steel and alloy producers achieve consistent furnace performance while controlling energy and material costs.

What Are UHP Graphite Electrodes?

UHP (Ultra High Power) graphite electrodes are specially engineered carbon conductors used in high-capacity electric arc furnaces. They are capable of carrying very high current loads and sustaining extreme temperatures exceeding 3000°C.

These electrodes are manufactured from ultra-pure needle coke and coal pitch binder, which are processed under carefully controlled thermal and mechanical conditions to ensure maximum conductivity and strength.

Distinctive features of Rongsheng’s UHP graphite electrodes include:

-

Low electrical resistivity, ensuring efficient power transfer.

-

High bulk density, providing mechanical durability under heavy furnace loads.

-

Excellent oxidation resistance, minimizing consumption and extending service life.

-

High thermal conductivity, improving heat distribution within the furnace.

-

Precision machining, ensuring tight connections and consistent performance.

The result is a product that not only endures the intense conditions of steelmaking but also enhances overall production efficiency.

The Importance of Raw Material for Electrodes

Every high-performance electrode begins with the right raw material for electrodes. Rongsheng recognizes that the composition and purity of these materials directly determine the quality and durability of the final product.

1. Needle Coke

This is the core raw material in UHP electrode production. It has a highly ordered molecular structure that allows for low thermal expansion and superior electrical conductivity. Rongsheng sources only high-quality petroleum and coal-based needle coke to achieve the necessary purity and crystalline alignment.

2. Coal Pitch Binder

Used to bind carbon particles, coal pitch contributes to electrode strength and density. Rongsheng uses refined pitch with controlled viscosity and carbon content to ensure uniform mixing and forming.

3. Additives and Impregnating Materials

Special impregnation processes with pitch or resins are used to increase density and oxidation resistance. This step significantly enhances electrode life during repeated furnace operations.

The synergy of these raw materials — combined with precise manufacturing — gives Rongsheng’s electrodes their distinctive consistency and reliability.

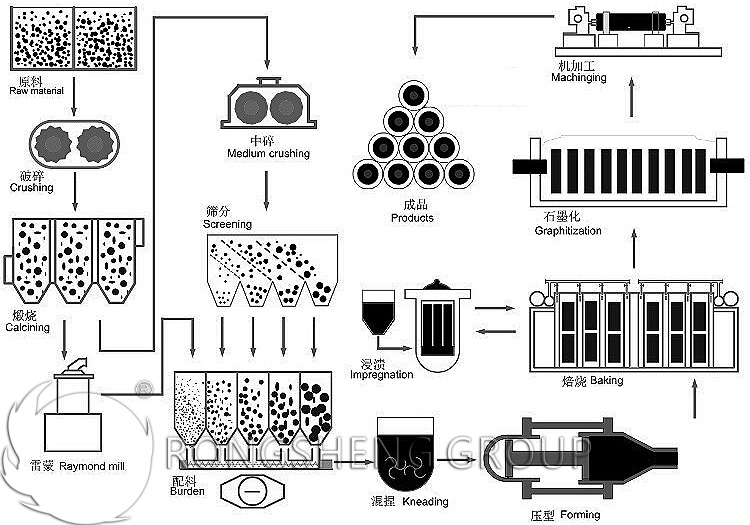

Manufacturing Process – From Raw Material to Finished Electrode

The transformation of raw carbon materials into fully graphitized UHP electrodes requires precision and advanced technology. Rongsheng’s production follows a systematic, multi-stage process to ensure every electrode meets global performance standards.

-

Raw Material Preparation – Needle coke is crushed, screened, and blended with pitch binder.

-

Mixing and Kneading – The materials are uniformly mixed and heated to achieve the right plasticity.

-

Forming – The mixture is extruded or molded into electrode shapes under high pressure.

-

Baking – Electrodes are carbonized at around 1000°C to form a solid carbon structure.

-

Impregnation – Baked electrodes are vacuum-impregnated with pitch to fill pores and enhance density.

-

Rebaking – After impregnation, electrodes are rebaked for additional strength and oxidation resistance.

-

Graphitization – The electrodes are heated to nearly 3000°C, converting carbon to crystalline graphite with high conductivity.

-

Machining – Electrodes and nipples are precision-machined for perfect fit and electrical continuity.

-

Inspection and Packaging – Each electrode undergoes electrical, mechanical, and dimensional testing before shipment.

Rongsheng’s strict quality control ensures that every electrode delivers consistent results, even under the heaviest furnace conditions.

Applications of Electric Arc Furnace Electrodes

Rongsheng’s electric arc furnace electrodes are used across multiple high-temperature industries, each requiring precise heat control and high energy efficiency.

1. Steelmaking in Electric Arc Furnaces

In EAF steelmaking, electrodes conduct electricity through scrap steel, creating intense arcs that melt the charge.

-

UHP electrodes are essential for large-capacity furnaces operating at high power densities.

-

They enable faster melting cycles and reduce total energy consumption.

-

Their high oxidation resistance ensures lower electrode wear per ton of steel produced.

2. Ladle Furnace Refining

After the initial melt, electrodes maintain heat and control temperature in ladle furnaces, where alloying and refining take place.

-

Rongsheng’s UHP electrodes provide stable current flow and precise temperature control.

-

The high purity of materials prevents contamination in high-grade steel alloys.

3. Ferroalloy and Silicon Smelting

In submerged arc furnaces, electrodes are inserted into the furnace charge to generate resistance heat.

-

They must withstand mechanical stress and chemical reactions with the molten material.

-

Rongsheng’s UHP electrodes perform reliably even in these high-load environments.

4. Non-Ferrous and Chemical Applications

UHP graphite electrodes are also used in processes that produce corundum, silicon carbide, and other refractory materials requiring consistent high temperatures and long operation times.

Why Choose Rongsheng as a Supplier of UHP Graphite Electrodes

Rongsheng’s position among global suppliers is built on its ability to combine quality, value, and technical support.

Advantages of Choosing Rongsheng:

-

Comprehensive Product Range: RP, HP, and UHP electrodes available in diameters from 100mm to 700mm.

-

Quality Assurance: ISO and CE-certified production processes ensure reliability and consistency.

-

Factory-Direct Pricing: Eliminating middlemen allows Rongsheng to maintain competitive graphite electrode prices.

-

Technical Expertise: Guidance on furnace optimization and electrode selection based on current density and furnace type.

-

Global Reach: Supplying customers in over 120 countries, including major steel and metallurgical enterprises.

Every shipment from Rongsheng represents not just a product, but a complete performance solution tailored to the customer’s operational goals.

Customer Case – High Efficiency in a 120-Ton Electric Arc Furnace

A steel producer in South America partnered with Rongsheng to upgrade its electrode system using UHP graphite electrodes. The switch resulted in:

-

14% reduction in electrode consumption per ton of steel.

-

Improved current stability and reduced power fluctuations.

-

Lower operational downtime due to fewer electrode changes.

This success demonstrates the long-term value of investing in high-quality electrodes made from premium raw materials.

Commitment to Sustainable Production

Rongsheng also integrates sustainability into every step of its production process.

-

Uses low-emission kilns and efficient graphitization furnaces.

-

Recycles waste carbon materials to minimize environmental impact.

-

Promotes longer electrode life, reducing industrial carbon consumption.

Through continuous innovation, Rongsheng contributes to greener, more energy-efficient steelmaking worldwide.

Conclusion

From carefully selected raw materials for electrodes to precision-engineered UHP graphite electrodes, Rongsheng exemplifies excellence in modern electrode manufacturing. Designed for reliability, conductivity, and durability, its electric arc furnace electrodes help steelmakers and foundries achieve higher productivity and energy efficiency.

As industries move toward sustainable, high-power production, Rongsheng continues to provide the tools — and the expertise — needed to power the furnaces of the future.

📩 Contact Rongsheng today for specifications and competitive quotations.

🌐 Visit the official website to learn more about UHP graphite electrodes and their industrial applications.