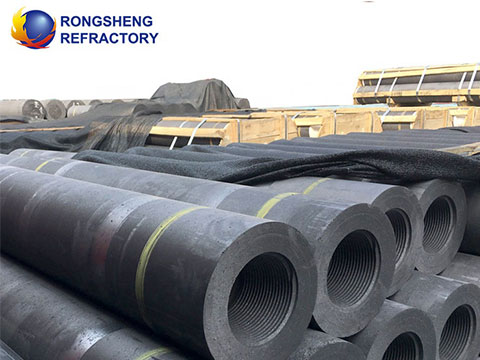

Rongsheng: Reliable Supplier of Discount UHP Graphite Electrodes and 600mm Models. In the fast-evolving world of steelmaking and metallurgy, graphite electrodes remain the core consumable for electric arc furnaces (EAFs). They bridge electricity and molten metal, enduring temperatures that can surpass 3000°C while maintaining consistent conductivity.

As global demand for high-efficiency steel production continues to grow, industries are looking for electrodes that balance performance and cost. Rongsheng, a leading graphite electrode manufacturer, delivers precisely that — offering discount UHP graphite electrodes that combine advanced production technology with dependable quality assurance.

Among its diverse product range, the UHP graphite electrode (600mm) stands out as a top performer, widely used in large-capacity EAFs across the world.

Understanding the UHP Graphite Electrode (600mm)

The UHP graphite electrode (600mm) is designed for ultra-high-power electric arc furnaces — the type used in large steel plants where maximum current density and long operational hours are common.

This electrode diameter, approximately 24 inches, allows greater power input and higher productivity while maintaining structural integrity under intense arc conditions.

Key Features of Rongsheng’s UHP Graphite Electrode (600mm):

-

Low Electrical Resistivity: Maximizes energy efficiency by minimizing power loss during melting.

-

High Density and Strength: Withstands furnace feeding pressure and prevents breakage.

-

Superior Thermal Conductivity: Ensures uniform temperature distribution within the furnace.

-

Excellent Oxidation Resistance: Extends service life, reducing electrode consumption per ton of steel.

-

Tight Nipple Connection Tolerance: Improves safety and stability during high-current operation.

Each electrode undergoes multiple inspections, ensuring consistent performance in the most demanding industrial environments.

Competitive UHP Graphite Electrode (600mm) Prices

One of the most attractive aspects of Rongsheng’s offering is its competitive pricing structure. The company combines large-scale production capability with direct factory supply, allowing customers to access discount UHP graphite electrodes without compromising on quality.

Factors Influencing UHP Graphite Electrode Prices:

-

Raw Material Quality: Needle coke and pitch binder cost fluctuations affect overall pricing.

-

Production Scale: Efficient, automated production at Rongsheng reduces per-unit manufacturing costs.

-

Customization Needs: Electrodes tailored to specific furnace designs may have variable pricing.

-

Global Supply Conditions: Market demand for steel and graphite materials impacts price trends.

By maintaining long-term relationships with reliable raw material suppliers and using advanced production technology, Rongsheng ensures customers always receive fair, transparent pricing for UHP and HP electrode grades.

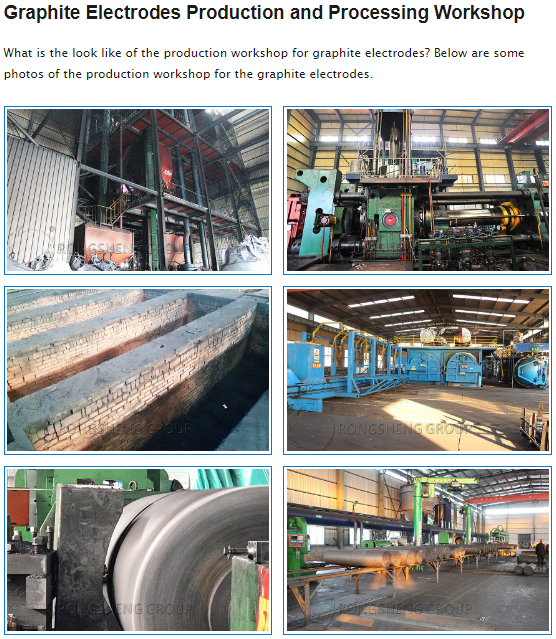

The Graphite Electrode Manufacturing Process

The quality of every graphite electrode starts with precise manufacturing. Rongsheng’s state-of-the-art facilities employ modern equipment and strict quality management systems to guarantee reliability and consistency across all electrode types.

Step 1: Raw Material Preparation

Premium needle coke, petroleum coke, and coal pitch are screened and crushed into uniform granules for consistent mixing and forming.

Step 2: Mixing and Forming

Carbon particles are mixed with a binder under controlled heat and pressure. The mixture is then extruded or molded into cylindrical electrode shapes.

Step 3: Baking

The green electrodes are baked at approximately 1000°C to carbonize the pitch and enhance strength.

Step 4: Impregnation

To increase density and reduce porosity, the baked electrodes are vacuum-impregnated with pitch.

Step 5: Rebaking and Graphitization

After impregnation, the electrodes undergo a second baking, followed by graphitization at nearly 3000°C. This process transforms amorphous carbon into crystalline graphite, providing high conductivity and thermal stability.

Step 6: Machining

CNC precision machining ensures the electrodes and nipples fit perfectly, allowing tight, stable connections during furnace operation.

Step 7: Testing and Packaging

Every electrode is tested for mechanical strength, resistivity, and density before being carefully packed for shipment.

Through these meticulous stages, Rongsheng guarantees that each electrode performs to international standards — a key reason it is trusted by steel plants, alloy producers, and foundries in over 120 countries.

Applications of UHP Graphite Electrodes in Modern Industry

While the main use of UHP graphite electrodes lies in electric arc furnace steelmaking, their performance characteristics make them essential across various high-temperature industrial applications. Rongsheng’s product versatility allows adaptation to multiple fields.

1. Electric Arc Furnace Steelmaking

The largest consumer of graphite electrodes, EAF steelmaking accounts for nearly 80% of total electrode usage.

-

UHP electrodes conduct high current to melt scrap steel efficiently.

-

The stable arc temperature enables faster melting cycles and reduced energy consumption.

-

Rongsheng’s electrodes exhibit a low breakage rate, minimizing production downtime.

2. Ladle Furnace Refining

During refining, electrodes maintain molten steel temperature and composition. Rongsheng’s UHP grade offers precise control, enhancing metallurgical quality.

3. Ferroalloy and Silicon Smelting

In submerged arc furnaces, UHP electrodes generate resistance heat to produce ferroalloys, silicon metal, and calcium carbide. Their high oxidation resistance ensures longer life even under continuous high-load conditions.

4. Non-Ferrous and Chemical Manufacturing

Electrodes also power high-temperature furnaces used to produce materials such as silicon carbide, corundum, and advanced ceramics — industries that require stable conductivity and thermal control.

Advantages of Choosing Rongsheng as a UHP Graphite Electrode Supplier

Rongsheng stands out among graphite electrode manufacturers due to its combination of scale, quality, and service.

Core Advantages Include:

-

Full Product Range: RP, HP, and UHP electrodes available in diameters from 100mm to 700mm.

-

Advanced Manufacturing Facilities: Automated equipment and strict process control ensure product uniformity.

-

International Certifications: ISO, CE, and SGS compliance guarantee reliability.

-

Factory-Direct Pricing: Eliminates middlemen to offer discount UHP graphite electrodes to global buyers.

-

Technical Support: Provides guidance for furnace power optimization, electrode selection, and consumption reduction.

These strengths have made Rongsheng a trusted partner for steel companies, alloy manufacturers, and material producers seeking long-term performance and cost benefits.

Customer Success Example – Improving Furnace Efficiency with UHP 600mm Electrodes

A European steel plant partnered with Rongsheng to replace its previous electrode supplier for a 150-ton EAF operation. After switching to UHP graphite electrodes (600mm), the plant achieved:

-

15% reduction in electrode consumption per ton of steel.

-

Shorter melting cycles due to higher conductivity and arc stability.

-

Lower production costs thanks to longer electrode lifespan and competitive pricing.

These measurable improvements demonstrate Rongsheng’s capability to deliver both technical and financial value to its clients.

Commitment to Sustainability

Rongsheng continues to invest in eco-friendly electrode manufacturing through:

-

Energy-efficient furnaces and waste heat recovery systems.

-

Recycling of carbon materials to reduce waste.

-

Development of low-emission baking technologies.

By prioritizing sustainability, the company ensures that its products not only perform well but also align with the global steel industry’s environmental goals.

Conclusion

From discount UHP graphite electrodes to high-performance 600mm models, Rongsheng delivers durable, efficient, and cost-effective products that meet the needs of modern electric arc furnaces.

Backed by years of experience in graphite electrode manufacturing, advanced equipment, and a customer-first philosophy, Rongsheng continues to set standards in the electrode industry — ensuring that every customer, whether a global steel giant or a regional foundry, receives reliable quality and value.

📩 Contact Rongsheng today for current UHP graphite electrode (600mm) prices or customized solutions.

🌐 Visit the official website to learn more about Rongsheng’s electrode production, specifications, and worldwide applications.

Rongsheng offers premium discount UHP graphite electrodes, including 600mm models, produced through advanced graphite electrode manufacturing technology to ensure performance, reliability, and cost efficiency in modern steelmaking.